Consultation:

Inquiry & Distribution:

Jahrelange Erfahrung, Freude an der Herausforderung und modernste Bewässerungstechnik ermöglichen es uns Ihr Wasser effizient und ressourcenschonend einzusetzen!

Gemeinsam mit Ihnen erarbeiten wir gerne ein, auf Ihre Bedürfnisse und Gegebenheiten zugeschnittenes, Bewässerungskonzept.

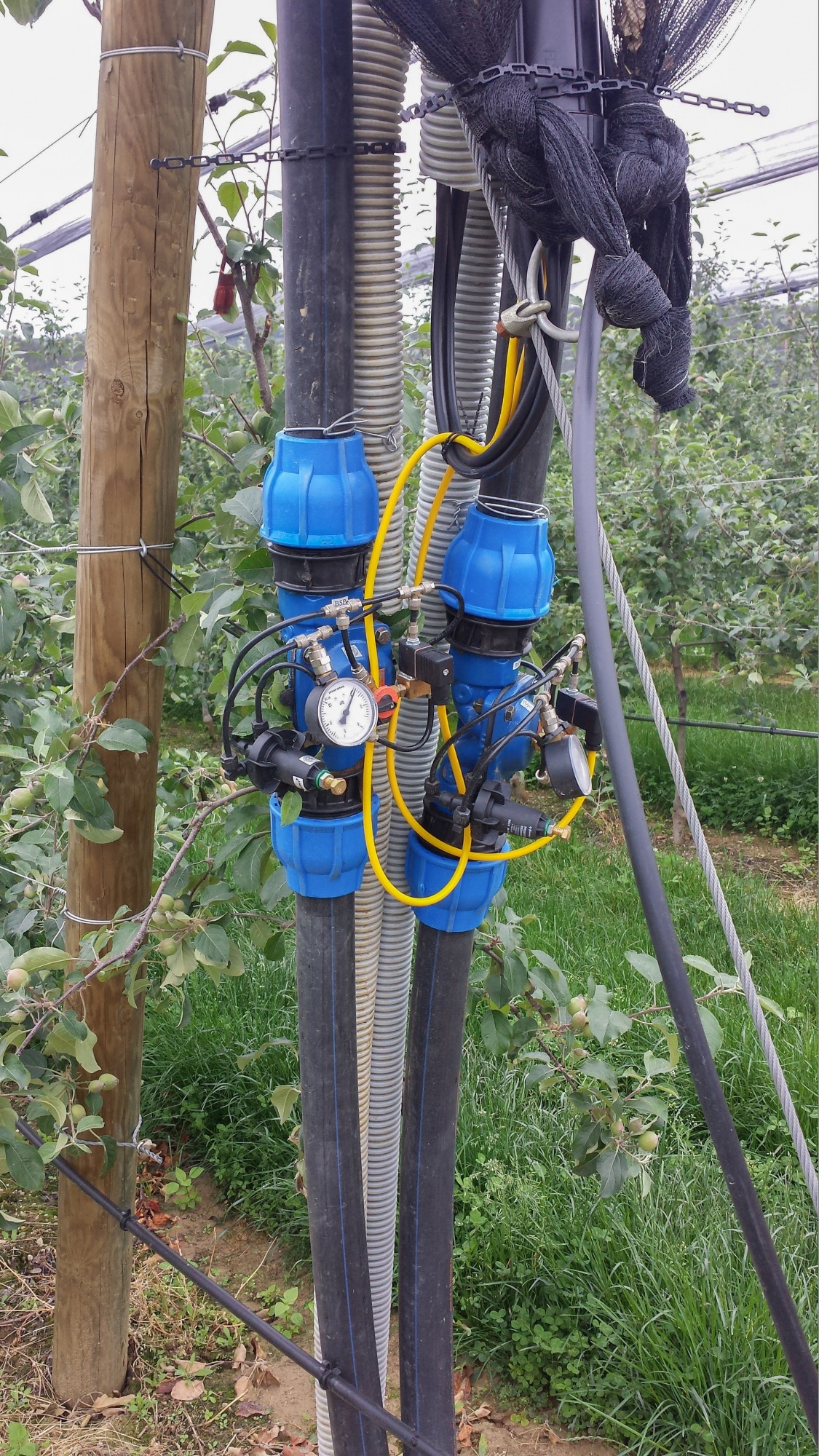

Mehrzweckberegnung

Frostbewässerung

- Wassersparend bis -4°C:

verminderter Wasserausstoß von ca. 35m³/h/Ha. - Frostschutz bis -8°C:

hoher Wasserausstoß zwischen 45 und 50m³/h/Ha - Geringere Regnerabstände mit kleineren Düsen ermöglichen auch bei Wind eine optimale Verteilung.

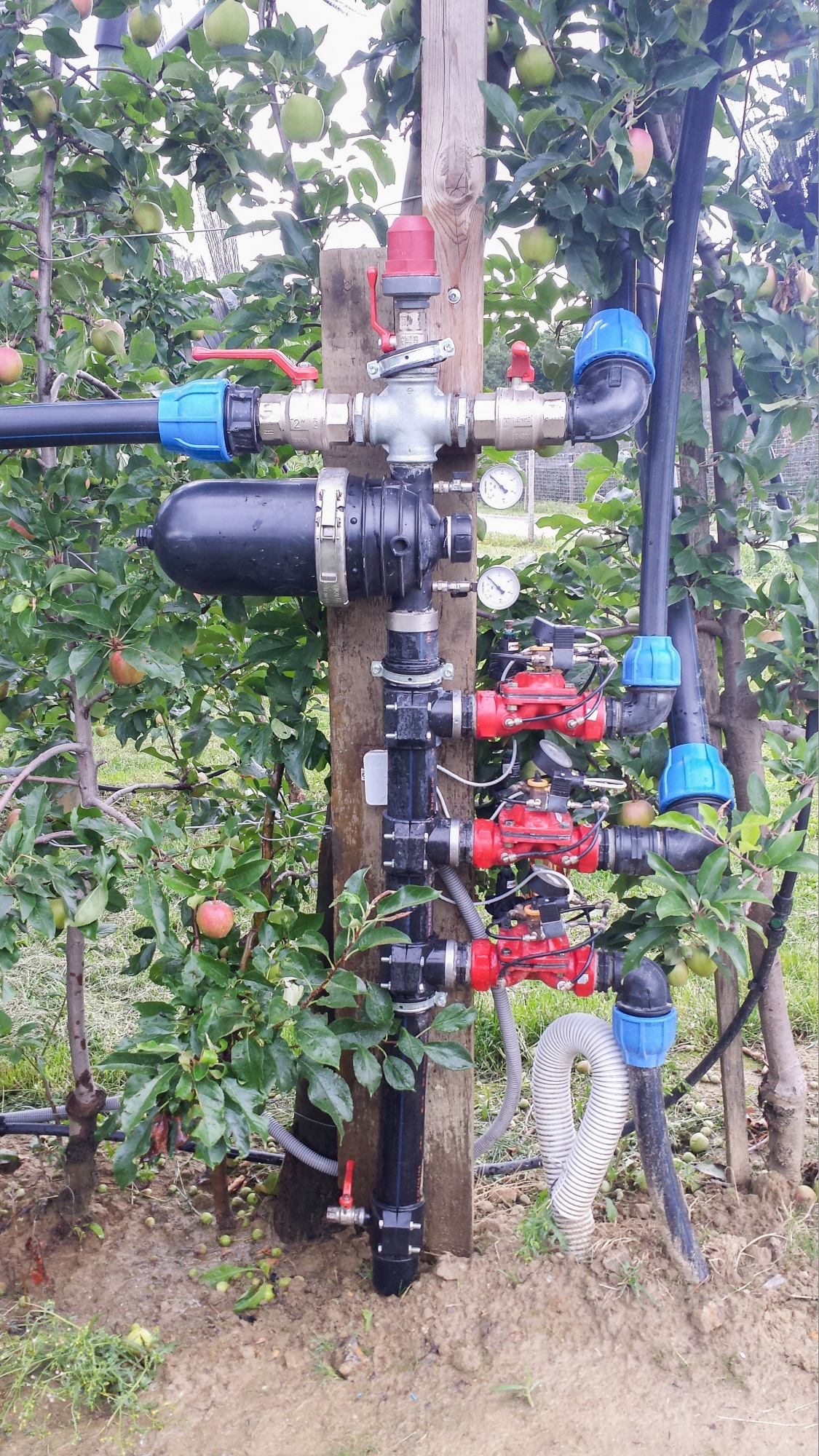

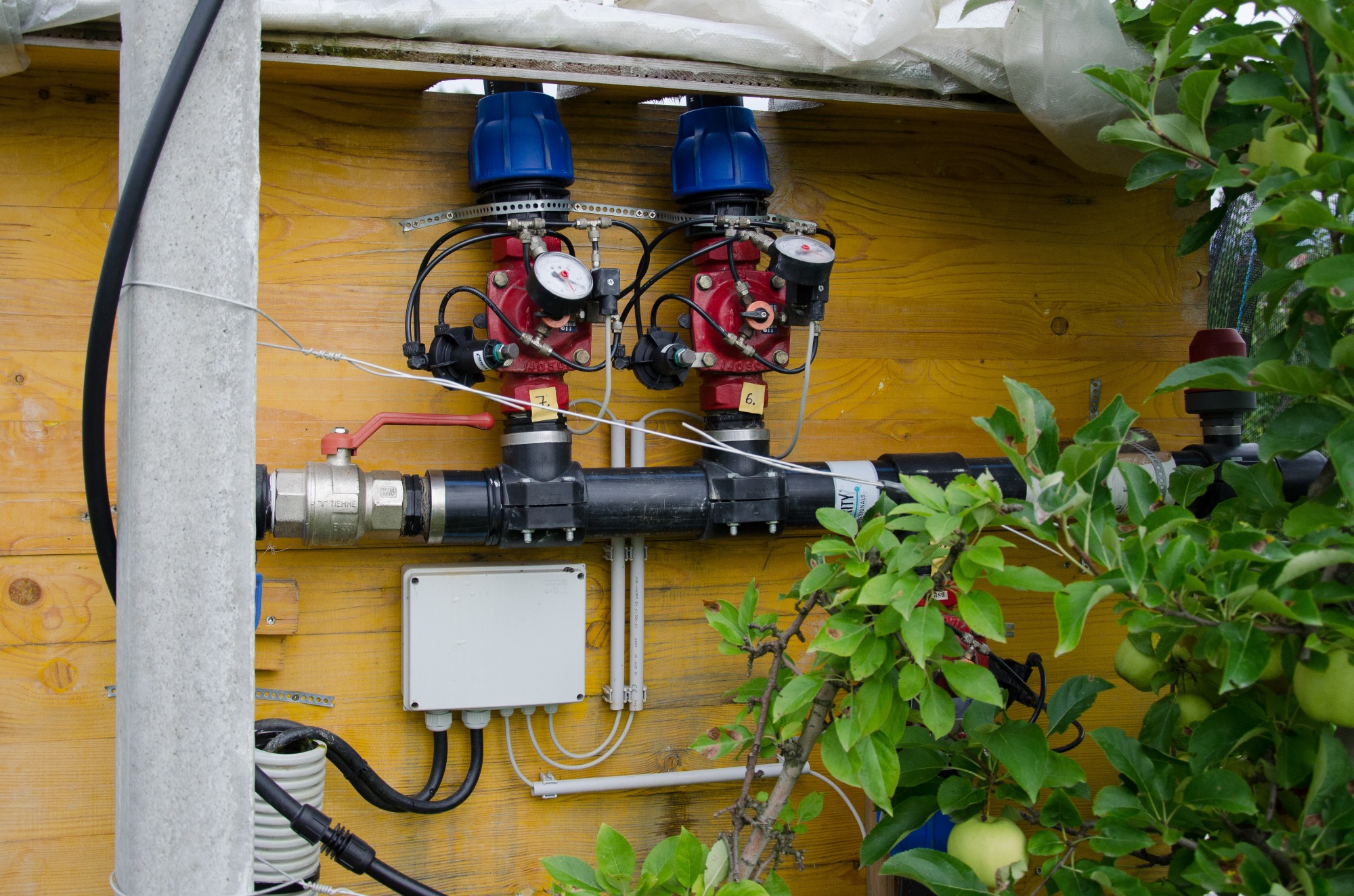

Stationäre Spritzanlage

- Die Injektion von Schwefelkalkbrühe ist seit 2009 in Österreich erlaubt.

- Nur 15 Minuten Zeitaufwand pro Zone

- Variable Zonengröße von 0,5 bis 10 Ha

- Der Betrieb ist zu jedem Zeitpunkt der Infektion möglich, auch bei Wind und/oder Regen.

Klimatisierende Beregnung

- Klimaausgleich an heißen Tagen

- Befeuchten der Beregnungsfläche durch die Überkronenbewässerung

- Durch das Beregnen der Fläche steigt die Luftfeuchtigkeit und lässt die Umgebungstemperatur sinken.

- Ein Temperaturausgleich von 4 - 5°C ist durchaus möglich.

Trockenbewässerung

- Durch die Überkronenbewässerung werden alle Bereiche, von den Wurzeln, über die Grünfläche bis hin zu den Blättern, erreicht.

- Eine rasche Versorgung wird ermöglicht.

- Das Wasser wird von den Pflanzen über schon bestehende Wurzelverzweigungen aufgenommen.

Weitere Vorteile

- Grünstreifenbewässerung

- Erosionsschutz

- Humusaufbau

- Düngung

Download: Mehrzweckberegnung

Fruit Security Broschüre zu Mehrzweckberegnung als PDF downloaden ...

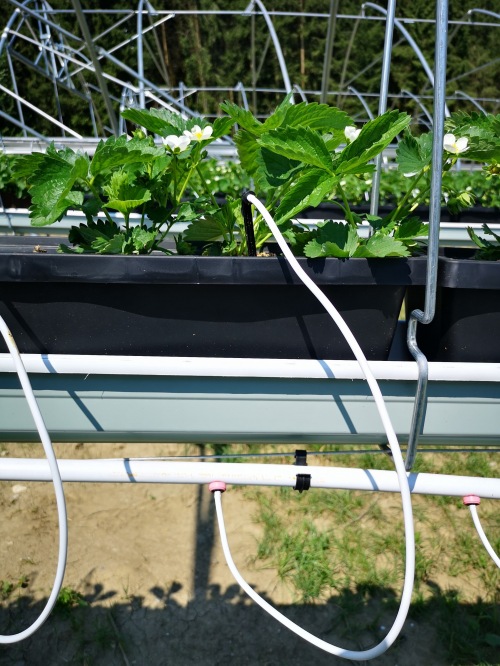

Tropfbewässerung

Bewässerungsstrategien

- Auslaufende Tropfbewässerung

- Einmal täglich

- Die Bewässerungsdauer ist abhängig von der gewünschten Wassergabe und vom Wasserausstoß

- Optimal für schwere Böden mit großer Speicherkapazität

-

Nichtauslaufende Tropfbewässerung

-

Mehrmals täglich mit kurzen Intervallen

-

Gleichmäßige Wasserversorgung des Wurzelbereiches, dadurch stressfreiere Wachstumsbedingungen für die Pflanze

-

Sehr gute Durchlüftung

-

Gleichmäßige Wasserverteilung in Hanglagen

-

Sehr gut geeignet für leichte und sandige Böden

-

Tropfrohr

- Integrierte Tropfer

- Variabler Tropferabstand (25 m, 30cm, 50 cm, 60 cm, …)

- Verschiedene Tropfergrößen (0,9 l/h, 1,6 l/h, 2,1l/h, …)

- Druckkompensierend (0,8 Bar - 3,5 Bar)

- Tropfstop auf Wunsch bei 0,14 Bar

- Antisyphon

- Rootguard - Wurzelwuchsbarriere auf 6 Jahre garantiert; prüfbar und nachfüllbar

- Einzeltropfer

- Erhältlich als fertig montiertes Produkt oder mit losen Tropferteilen zur Selbstmontage

- Tropfverteiler mit Spießen

- 1-fach

- 2-fach

- 4-fach

- Variable Microschlauchlänge

- Tropfrohr und Microschlauch sind außen und innen weiß, was die Algenbildung verhindert.

Vorteile

- Wassersparend und effizient

- Geringer Energieaufwand

- Niedrige Verdunstung

- Optimale Pflanzenversorgung

Erweiterungsfeatures

- Fertigation

- Steuerung durch Einsatz von Feuchtesensoren

- Kontrolle anhand von Wasserzählern

Download: Tropfbewässerung

Fruit Security Broschüre zu Tropfbewässerung und Tropfschlauch als PDF downloaden ...

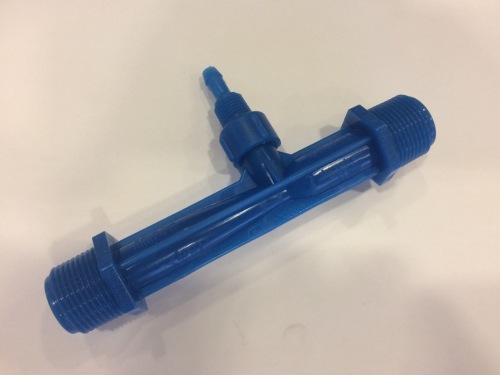

Fertigation

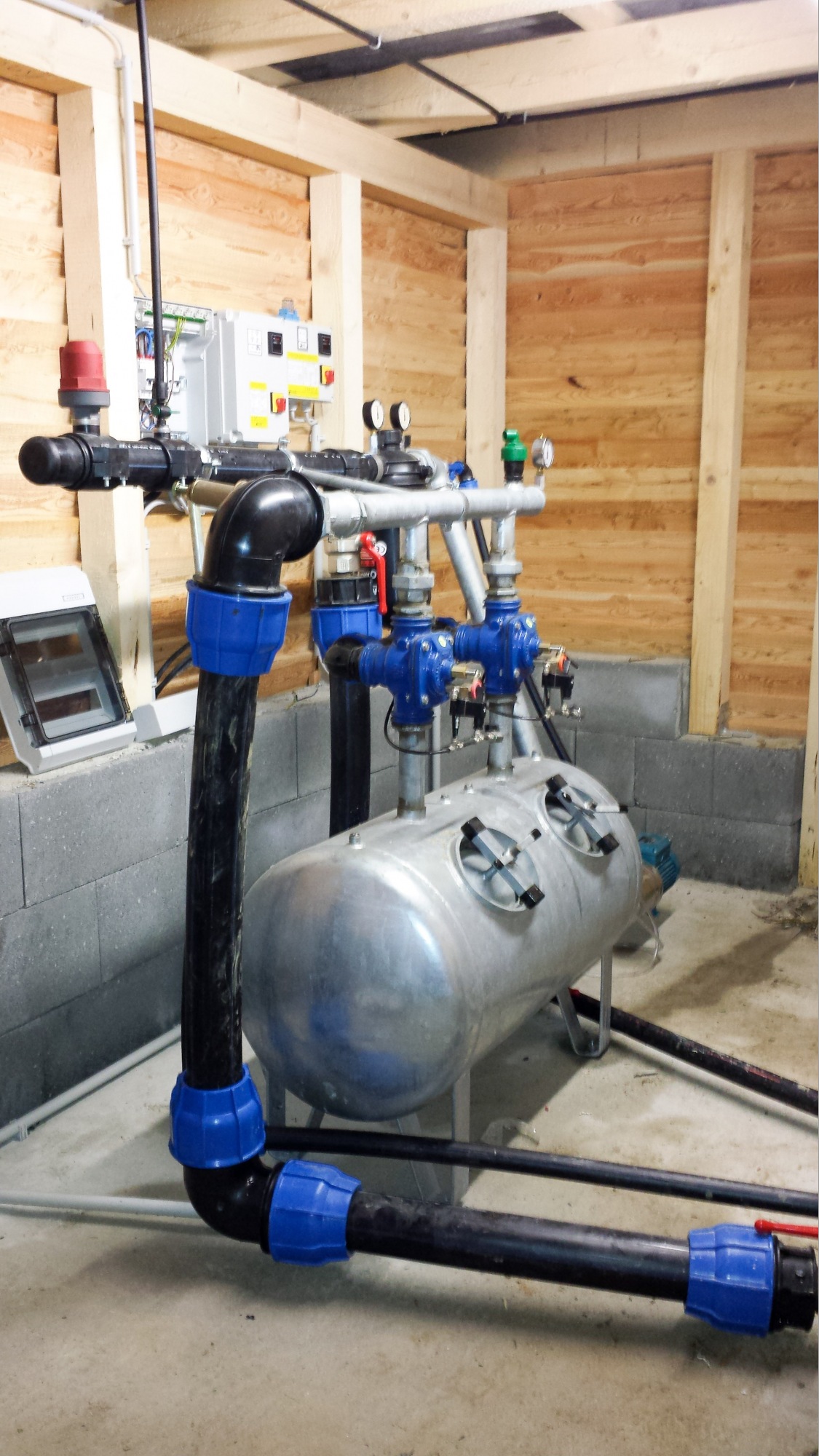

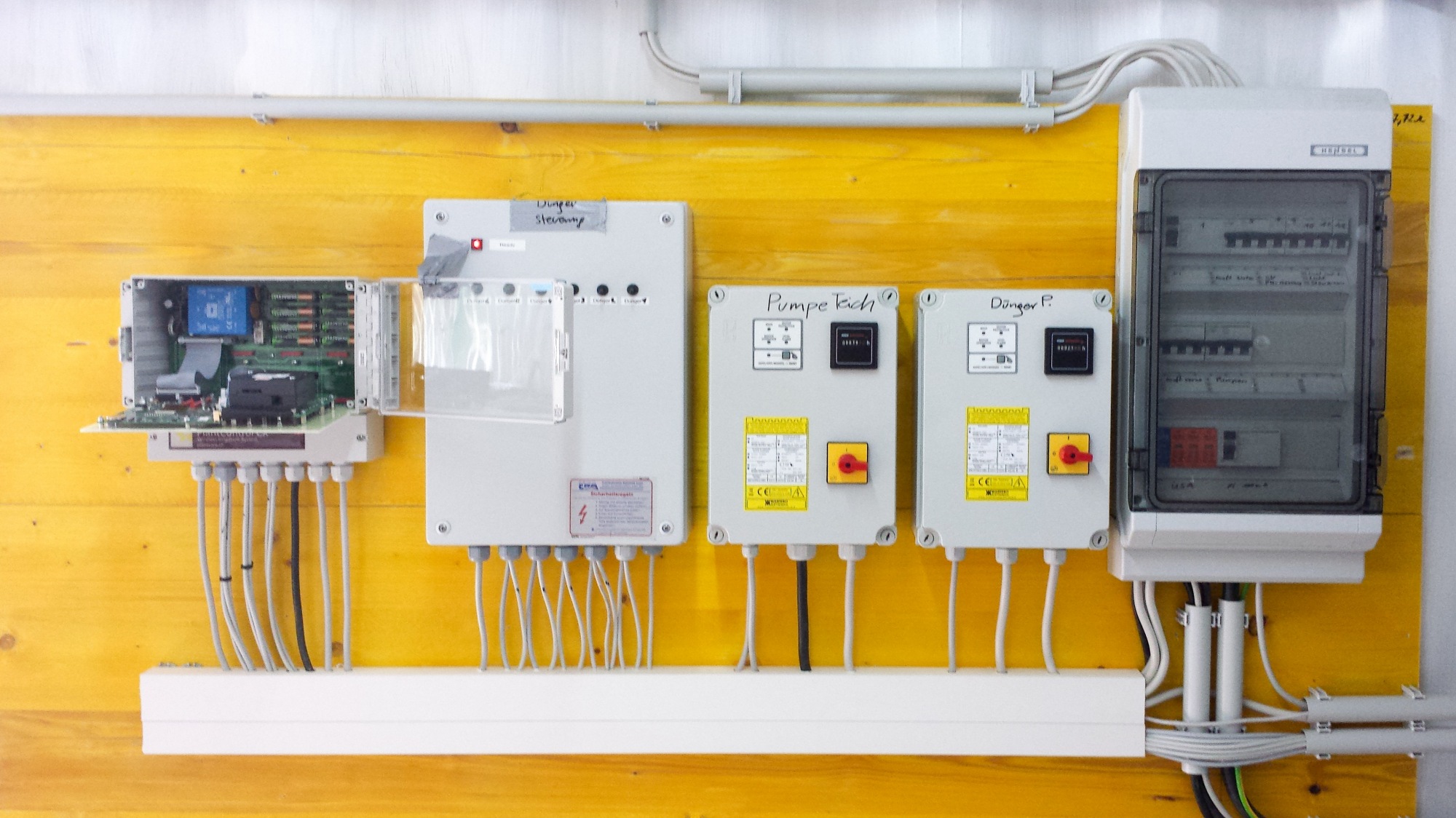

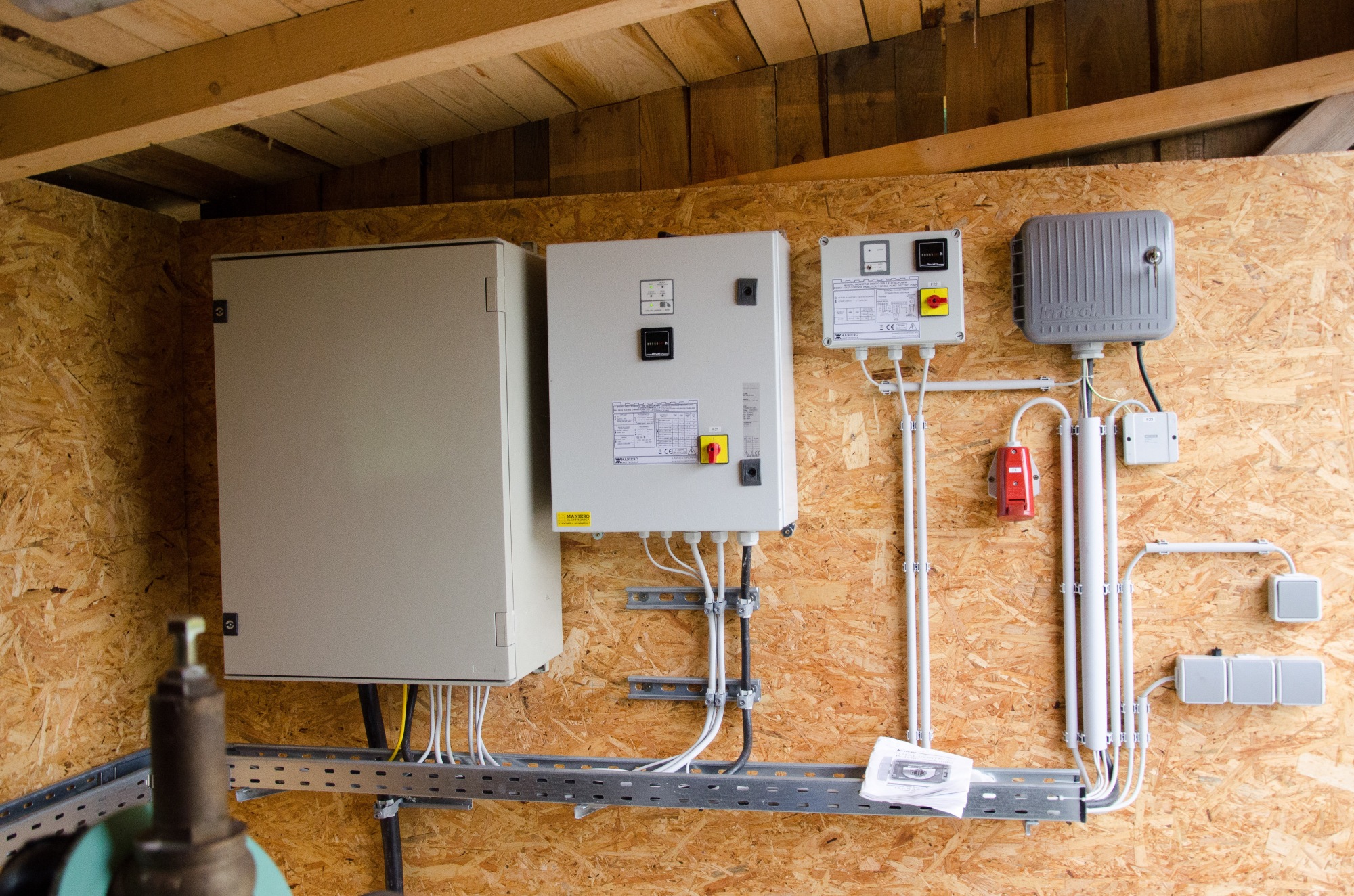

Volumetrische Fertigation

- Venturi Injektordüse

- Stromlos oder mit Drucksteigerungspumpe

- Verschiedene Drücke vor und nach der Venturidüse erzeugen einen Unterdruck im Ansaugschlauch.

- Manuelle Mengenregulierung bei verschiedenen Feldgrößen

- Injektorpumpe

- 230 V oder benzinbetrieben

- Selbstansaugende Injektorpumpe

- Der Dünger wird mit Überdruck in das System injeziert.

- Mengenregulierung nur durch unterschiedliche Injektionszeiten.

- Proportionale Dosierpumpe

- Stromlos

- Mixrite oder Dosadron

- Genaue Dosierung bei Inlinesystem

- Säurehaltige Dünger nur bis 2,5 m³/h

- Proportionale Membran- oder Kolbenpumpe

- 230 Volt

- Injekton mit Überdruck in das System

- Die Menge wird durch Impulse von einem Wasserzähler gesteuert.

- Optional auch mit EC- und pH-Sensor gesteuert

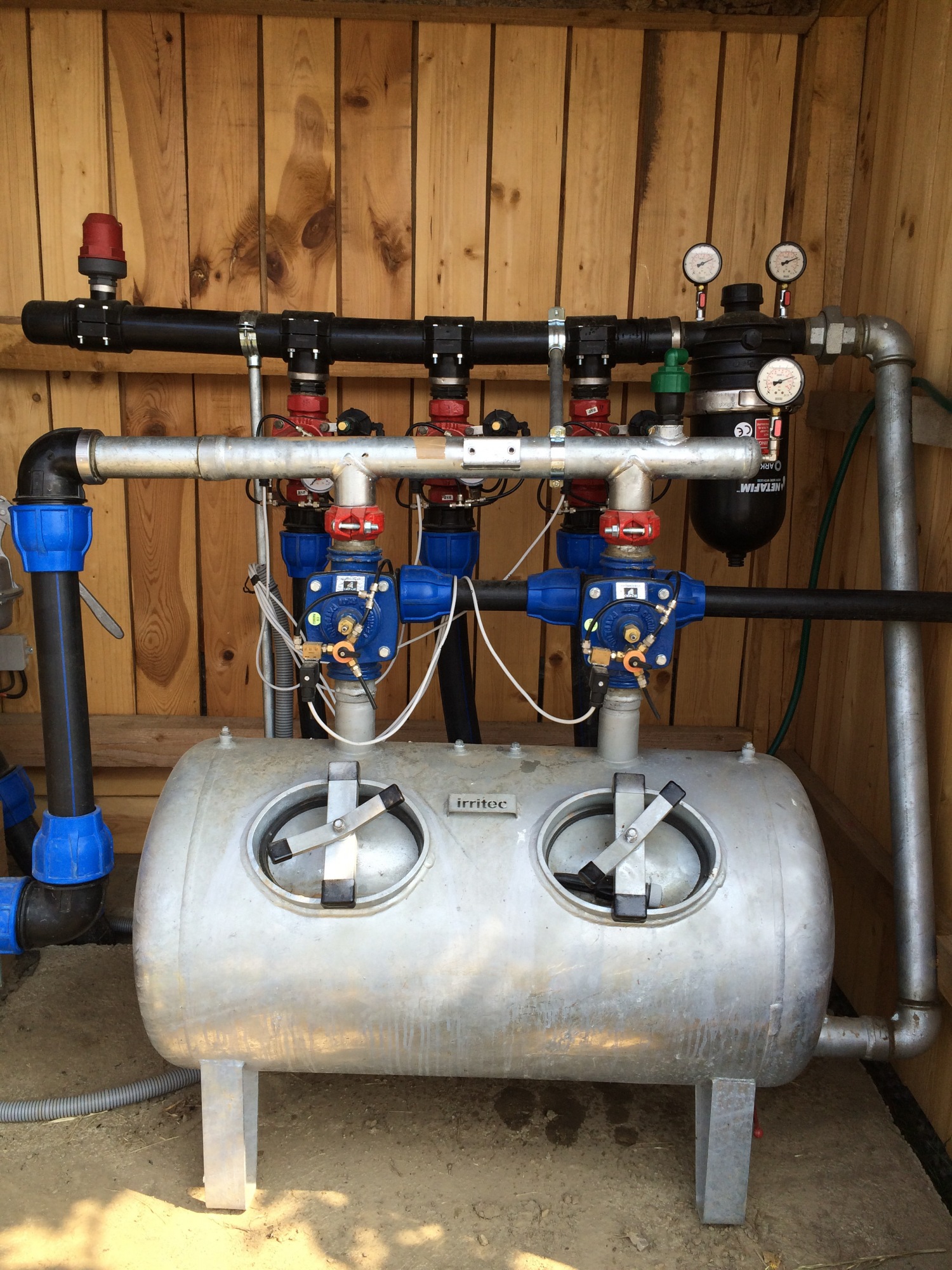

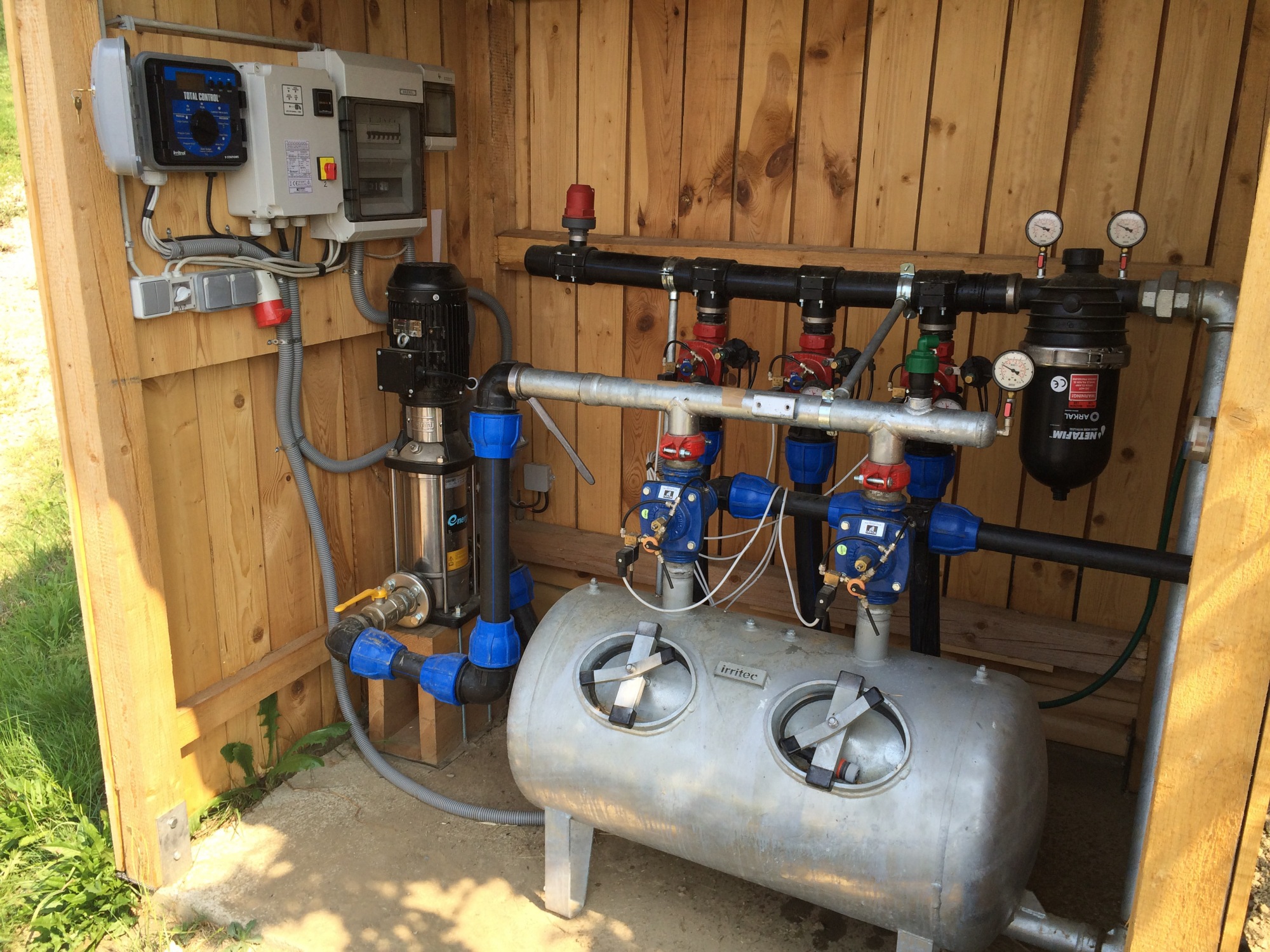

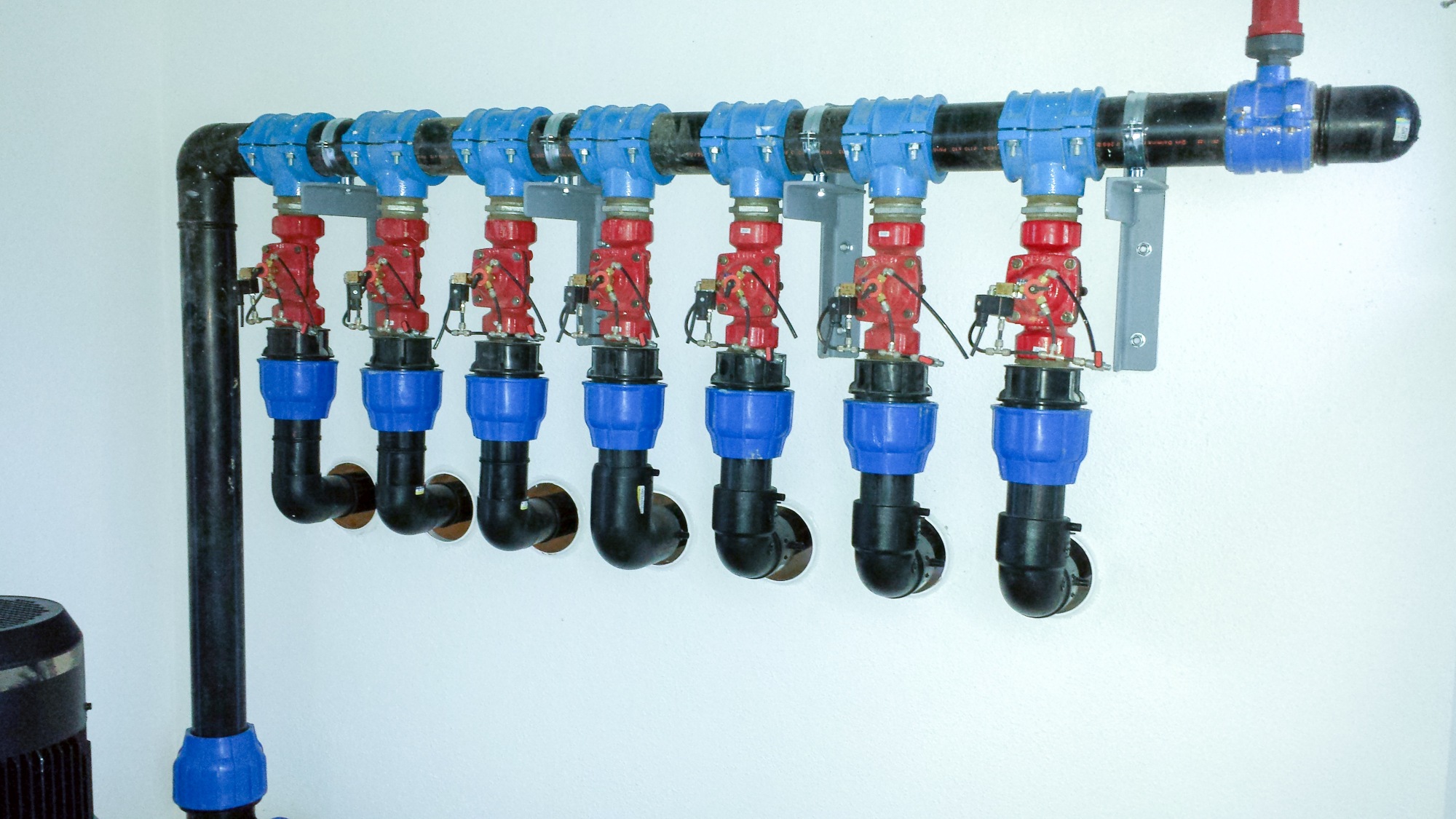

Vollautomatische Düngermischanlagen

- Inline- oder Bypasssysteme

- EC- und pH-Sensor gesteuert

- 1 Säureinjektor

- Bis zu 12 Düngerinjektoren

- Verschiedene Düngerrezepturen

- Stand-alone oder über eine zentrale Bewässerungssteuerung

- Automatische Regulierung der EC- und pH-Werte

Download: Fertigation

Fruit Security Broschüre zu Fertigation als PDF downloaden ...

English

English

Deutsch

Deutsch